“We’re doing things that people have not done before,” said Andrew Braham, assistant professor of civil engineering. “I believe what we’re doing in the lab here, 20 years from now will be standard procedures.”

Braham’s research focuses on transportation materials and sustainability. He studies the two main kinds of paving materials, asphalt concrete and portland cement concrete, looking for new and better ways to use these materials on our roads.

Portland cement concrete (commonly referred to as concrete) is composed of aggregate held together by rigid portland cement.

Asphalt concrete (commonly referred to as asphalt) is a flexible material. It’s made of aggregate and asphalt binder. Air trapped in the binder makes asphalt give slightly under pressure.

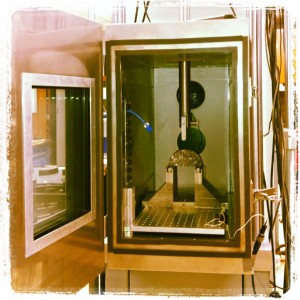

Braham’s MTS Load Frame is a universal testing device for paving materials. It is able to apply a 5000 pound load on a sample, pulse up to 25 times a second and its environmental chamber ranges from minus 50 degree Celsius to 60 degrees C.

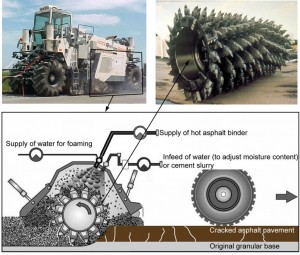

One of the biggest issues in the field of transportation materials is road rehabilitation, and researchers like Braham are looking for ways to repair roads more sustainably. One of the methods Braham is studying is called Full Depth Reclamation. In this process a milling machine grinds up the top layers of a worn asphalt road. The milled asphalt is mixed with more binder, then replaced.

Illustration of the Full Depth Reclamation process, in which a milling machine breaks up and recycles old pavement.

Recycling paving materials in this way cuts down on energy use and waste, and Braham is looking for ways to further improve this technique by analyzing the effects of extra ingredients, such as asphalt foam, that can added to the recycled asphalt to improve the efficiency of the process and the performance of the finished product.

“The whole concept of mix design—what to add to it, how much to add—that’s a big unknown with full depth reclamation. There’s no established mix design,” Braham explained.

Braham understands that the key to finding answers is perseverance. “I would say probably half of what we do in the lab probably won’t go much further,” he admitted. “But the other half is what’s really exciting, because you know that people will be using that in the future.”