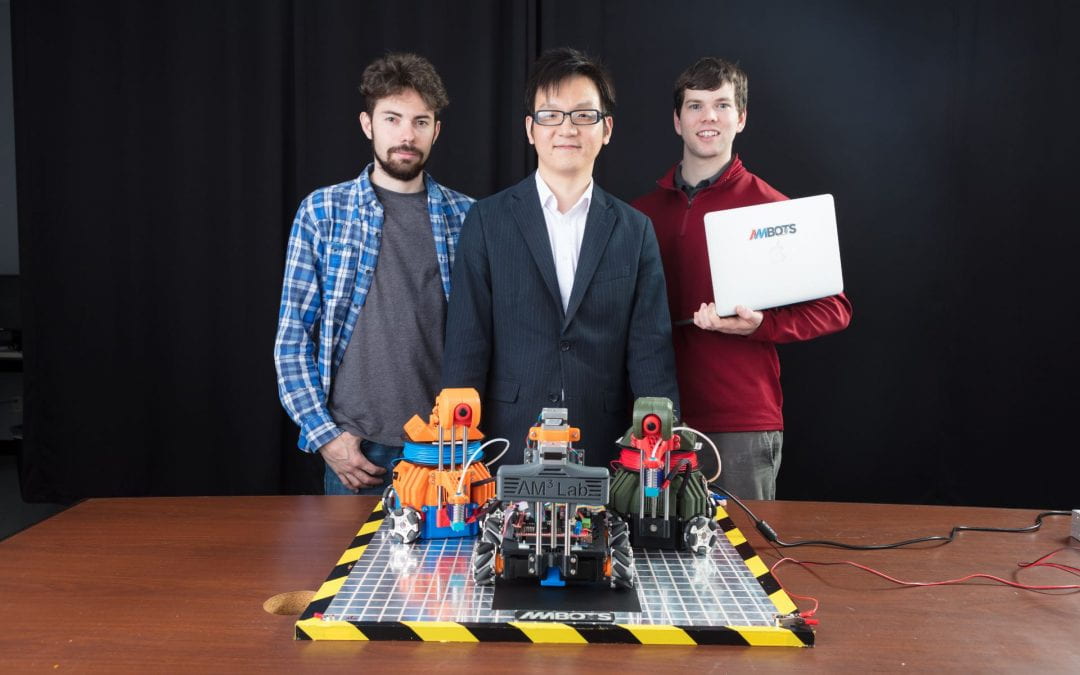

Pictured above:Lucas Marques, Assistant Professor of Mechanical Engineering Wenchao Zhou and Austin Williams started AMBOTS to advance their vision for the next generation of manufacturing technology. The group conducts their research in the Arkansas Research and Technology Park.

THE FUTURE OF PRODUCT MANUFACTURING can be found in a laboratory at the Arkansas Research and Technology Park, where Wenchao Zhou, Lucas Marques and Austin Williams, all younger than 35, are building a swarm of robots. These “AMBOTs,” as they call them, work together to perform complex manufacturing tasks, including 3D printing, automated assembly, screw-driving, cutting, machining and welding.

“Right now, we’re trying to figure out the minimum set of robots needed for a generic digital factory,” says Zhou, a professor of mechanical engineering and director of the AM3 Lab, where he, Marques and Williams are developing the next generation of 3D printing technologies.

BUILDING PRODUCTS ONE LAYER AT A TIME

Additive manufacturing, known as 3D printing, is the process of building an object by depositing layer upon layer of material, be it plastic, resin, steel, or even soil and biological tissue. Companies all over the world use this technology to make things like cuff links, wedding rings, sneakers, engine parts and orthopedic implants. But these products have a few things in common that speak to their limitations: They take considerable time to make and they’re relatively small.

There is the problem of scale with current 3D-printing techniques. Conventional 3D printers require a box-like structure that supports the print head. Scaling those support structures up increases costs quickly, making it infeasible to build a printer that could manufacture large products like an airplane.

Zhou, Marques and Williams worked around this problem by building a mobile, autonomous, 3D-printing vehicle that can work in concert with dozens, if not hundreds of other robots, like a swarm of bees. The researchers will need to scale up their robots to be able to take on a project like a house or an airplane, but they’re not worried about this. As Williams points out, factories are already using large forklifts that have a chassis and wheels similar to the AMBOTs.

AM-CUBED

Earlier this year, Zhou, Marques and Williams started a company, named AMBOTS, to move their vision and discoveries forward. The University of Arkansas provided the startup funding for the project. Zhou is the chief technology officer, Marques the chief design officer and Williams the chief software architect. All are listed as co-founders. Within two years, Zhou said, they hope to set up a mini factory at the Arkansas Research and Technology Park, to serve as a model for a network of generalized digital factories around the globe, each equipped with thousands of specialized autonomous robots.

The “AM” in AMBOTS stands for “additive manufacturing,” the process commonly known as 3D printing. Zhou notes that “AM” also stands for advanced manufacturing, advanced modeling and advanced materials, or, as the name of the lab says, AM-cubed.

A SWARM OF ROBOTS

Zhou has worked with 3D-printing technology for more than a decade. At the U of A, with Marques’ and Williams’ help, he ran through several iterations of a mobile, wirelessly controlled robot that could lay down material and build crude, three-dimensional objects. They continued tweaking the design until settling on the current generation, a vehicle that performs to their satisfaction and serves as a model for a fleet of robots that will perform different

tasks. So far, in addition to a printing robot, or “printbot,” they have completed a digital-assembly robot that can “pick and place” parts.

These AMBOTs – 80 percent of which are made with 3D-printed materials – look like the fusion of the Mars Rover and a toy robot. They have anthropomorphic features and function with purpose and precision. You can hear their gears quietly turning and circuits humming. When the printbot lays down material, it sounds like a tattoo gun.

Each robot has a “unibody,” which is a chassis combined with a control panel, electronic circuits that control the machine’s components, wheels with a series of rubber pads that allow the robot to pivot precisely and move in any direction, and finally the “Z Stage,” a vertical column that moves the tool head up and down.

The printbot contains a printer attached to the tool head, a filament spool, which stores the filament material to be printed, and an extruder, which pulls the filament from the spool and sends it to the printer. The Z Stage is a critical component. The researchers focus on it to modify the robot to perform different tasks. To make the digital assembly robot, for example, they removed the extruder and filament spool from the printbot and attached a gripper to the tool head instead of a printer.

Old Bot vs. New Bot. Labeled: Mobile 3D Printer, Front Camera, Power Floor, Mobile Gripper, Optical Sensor.

INDIVIDUALITY DRIVES HUMANS

In the lab, Zhou hovers over the robots, while talking about the role of technology in the history of human development. Sometimes, he sounds more like a philosopher than a mechanical engineer.

“Manufacturing technology is a symbol of the level of human civilization,” he says. “For most of human history, craftsmen customized products, be it clothes, shoes or even weapons. But today, everything is mass produced, due to cost. We want to change this. We want to build generalized, autonomous factories that can produce anything for anyone, on demand and inexpensively.”

Zhou sees his robots as the means to achieve this goal. They will guide manufacturing away from mass production and back toward customization.

“Because individuality is what drives humans,” he says.

Follow the Ambots Team Online!

ambots.net

@Ambots3D